Isu tinoziva kuti jekiseni mold ine mold inofambiswa uye yakagadziriswa mold.Iyo mold inofambiswa inoiswa pane inofamba template yemushini wekuumba jekiseni, uye iyo yakagadziriswa mold inoiswa pane yakagadziriswa template yemushini wekuumba jekiseni.Munguva yekuumbwa kwejekiseni, mold inofambiswa uye yakagadziriswa mold inovharwa kuti igadzire gating system uye mhango.Kana mold yavhurwa, mold inofambiswa uye yakagadziriswa mold inoparadzaniswa kuti ibudise chigadzirwa chepurasitiki.Saka yakawanda sei yaunoziva nezvekushandiswa kwechigadzirwa ichi?Izvi zvinotevera sumo pfupi yezvidziviriro kusati kwaedza jekiseni mold.

Iwo ekudzivirira pamberi pejekiseni mold kuyedzwa anotsanangurwa sezvizvi:

1. Nzwisisa ruzivo nezve jekiseni mold: Zvinokurudzirwa kuwana dhizaini yekudhirowa kwejekiseni mold, kuiongorora zvakadzama, uyezve rega muinjiniya wejekiseni atore chikamu mubasa rekuyedza.

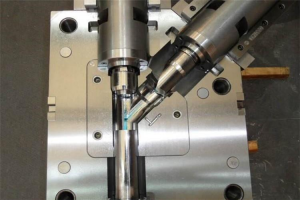

2. Chekutanga tarisa mashandiro emakanika pane bhenji rebasa: teerera kuti pane zvikwambo, zvisipo uye zvakasununguka zvikamu, kana kutsvedza kwechiumbwa chiri chaicho, uye pombi yemvura.

uye zvigadziriso zvemhepo zvekuvuza, uye kana kuvhurika kwejekiseni mold kuri ganhuriro, kunofanirwa kumakwa.Kana zviito zviri pamusoro zvinogona kuitwa zvisati zvaturika jekiseni mold, matambudziko anowanikwa pakurembera jekiseni mold anogona kudziviswa, uye ipapo yakapedzwa man-awa pakubvisa jekiseni mold anogona kudziviswa.

3. Kana zvakatemwa kuti kufamba kwechikamu chega chega chejekiseni mold kunopedzwa, zvinodikanwa kusarudza yakakodzera jekiseni molding muchina.

4. Paunenge uchirembera mold, zvinofanira kucherechedzwa kuti usati wavhara zvese zvimedu uye kuvhura mold, usabvisa kukiya uye kudzivirira kuti irege kudonha nekuda kwekureruka kana kuputsika mabhanhire.Mushure mekunge mold yaiswa, chiitiko chemuchina chechikamu chimwe nechimwe che mold chinofanirwa kunyatsotariswa, sekunge ndiro inotsvedza uye thimble iri kushanda nemazvo uye kana muromo wakabatana nechiteshi chekudyisa.

5. Paunenge uchivhara mold, iyo clamping pressure inofanira kuderedzwa.Munguva yemanyorero uye yakaderera-kumhanya clamping mashandiro, kutarisisa kunofanirwa kubhadharwa kuti utarise uye uteerere kune chero mafambiro uye manzwi asina kujairika.Nzira yekusimudza mold iri nyore chaizvo.Chinhu chikuru chekucherechedza ndechekuti gedhi re mold uye nozzle center zvakanyanya kuoma.Kazhinji, nzvimbo yacho inogona kugadziriswa ne test strip.

6. Sarudza yakakodzera mold tembiricha yekudzora muchina kuti uwedzere tembiricha yekuumbwa kune inodiwa tembiricha panguva yekugadzira maitiro.Mushure mekunge kutonhora kwe mold kwawedzera, tarisa kufamba kwechikamu chimwe nechimwe zvakare.Sezvo simbi ichigona kukonzera kufa-kucheka nekuda kwekuwedzera kwekupisa, kutarisirwa kunofanirwa kutorwa kuti chikamu chimwe nechimwe chitsvedze kudzivirira kutaura.

Nguva yekutumira: Jan-20-2022